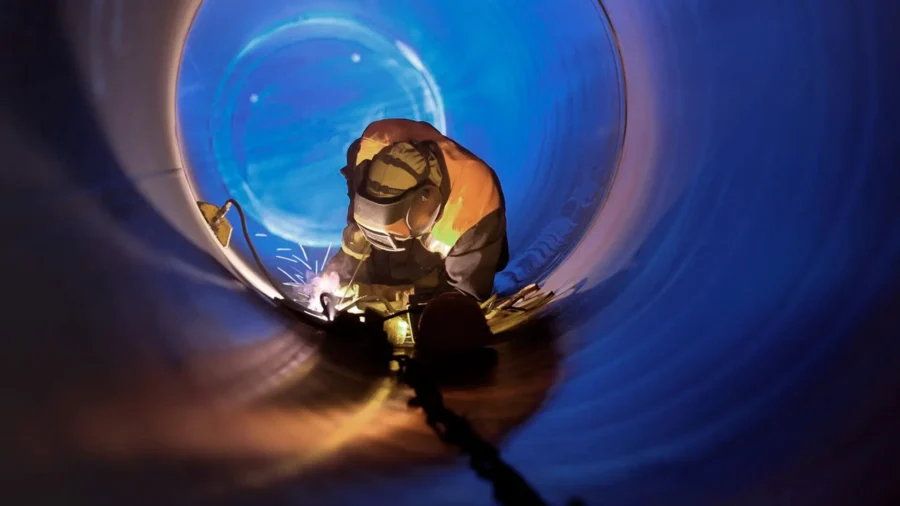

Fabrication of steel sructures and pipe spools at TCO

Scope of Work:

- Procurement: Obtaining raw materials in accordance with TCO requirements (if applicable).

- Fabrication: Creating steel structures and pipe spools.

- Surface Treatment: Sandblasting and painting of fabricated materials.

- Quality Assurance/Quality Control (QA/QC): Ensuring compliance with standards through inspections with client representatives.

- Delivery: Transporting the finished steel structures and pipes.

Supply of Materials and Equipment:

- Building and Assembly: Various construction tasks such as civil work, erecting steel structures, installing pipe racks and fencing, tank installation, piping installation and testing, cable installation (Electrical, Instrumentation, Telecommunication, Fiber Optic), equipment installation (Electrical, Instrumentation, Telecommunication), painting, and insulation work, as well as passive fire protection.

Project Goal:

The primary objective is the fabrication of steel structures and pipe spools to meet the needs of TCO.

Production Capacity:

The project aims to fabricate 2000 tons of structural steel.

Place of Project Implementation:

The project is located in the Atyrau region.

Timeline:

The project is set to be completed within 24 months.

This comprehensive plan covers the entire process from procurement to delivery and installation, ensuring the successful execution of the project within the specified timeframe and quality standards.